- Overview of radioactive contaminants and their impact

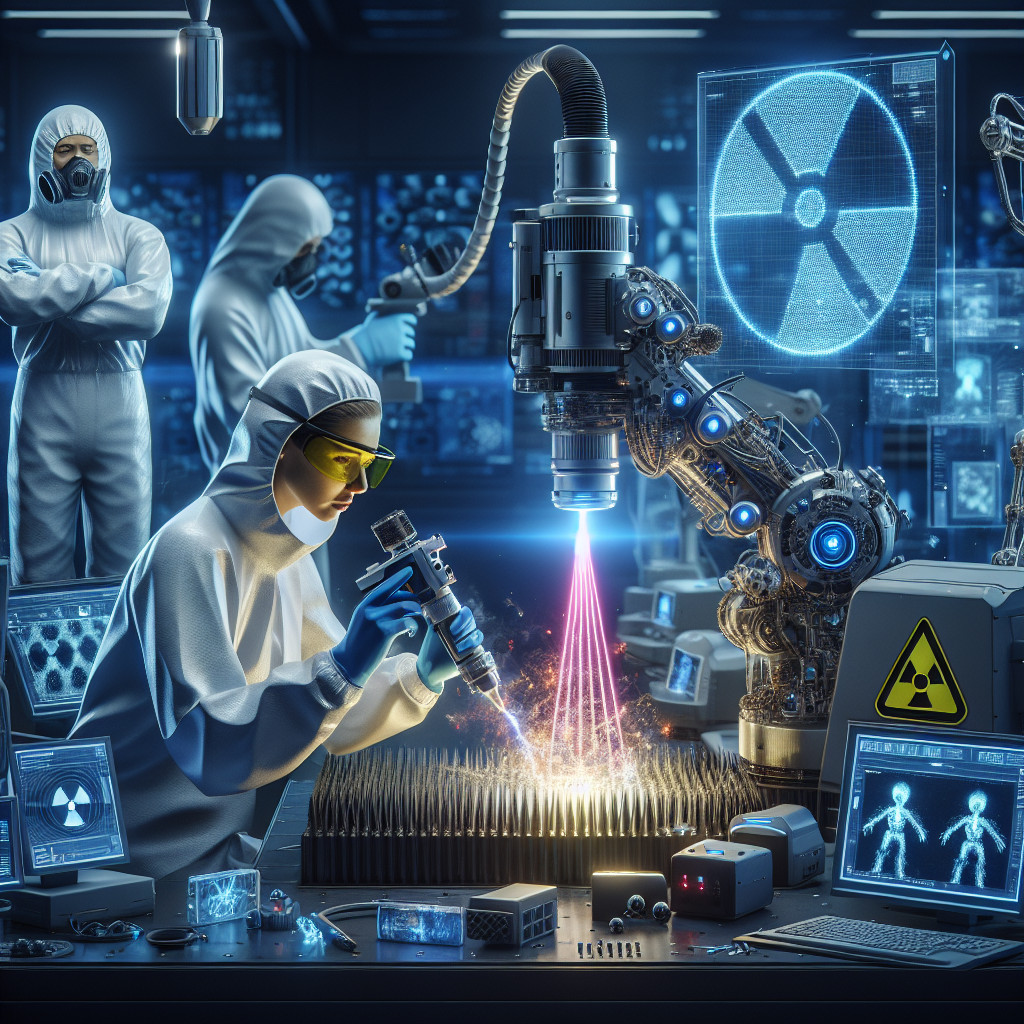

- Comparison of traditional cleaning methods vs. laser cleaning

- Safety considerations when using lasers for decontamination

- Environmental benefits of laser cleaning in radioactive decontamination

- Challenges and limitations of laser cleaning technology

- Case studies of failed laser cleaning attempts

- Integration of laser cleaning technology into existing decontamination processes

- Potential applications of laser cleaning in other industries

Overview of radioactive contaminants and their impact

Types of radioactive contaminants

There are several types of radioactive contaminants, each with its own unique properties and sources. Some common types include:

| Type | Description | Source |

|---|---|---|

| Uranium | A heavy metal that is used in nuclear reactors and weapons | Nuclear power plants, mining operations |

| Plutonium | A synthetic element used in nuclear weapons and reactors | Nuclear weapons production, nuclear reactors |

| Cesium-137 | A radioactive isotope produced in nuclear fission reactions | Nuclear power plants, nuclear accidents |

Impact of radioactive contaminants

Radioactive contaminants can have a range of impacts on human health and the environment. Exposure to high levels of radiation can cause acute radiation sickness, cancer, and genetic mutations. In the environment, radioactive contaminants can contaminate soil, water, and air, leading to long-term ecological damage.

Mitigating the risks of radioactive contaminants

There are several ways to mitigate the risks associated with radioactive contaminants. These include proper storage and disposal of radioactive waste, monitoring and regulating radiation levels in the environment, and implementing safety measures in nuclear facilities. Public education and awareness are also important in reducing exposure to radioactive contaminants.

Conclusion

Radioactive contaminants pose a significant threat to human health and the environment. Understanding the types of contaminants, their sources, and their impacts is crucial in developing effective strategies for managing and mitigating their risks. By taking proactive measures to control and reduce exposure to radioactive contaminants, we can protect ourselves and future generations from the harmful effects of radiation.

#radioactivecontaminants #radiation #nuclear #health #environment

frazy kluczowe:

– skutki promieniowania na zdrowie

– wpływ substancji radioaktywnych na środowisko

– sposoby ograniczania ryzyka związanego z substancjami radioaktywnymi

Comparison of traditional cleaning methods vs. laser cleaning

Traditional Cleaning Methods

Traditional cleaning methods involve physical or chemical processes to remove contaminants from surfaces. These methods can be effective, but they often require a lot of time and effort to achieve satisfactory results. Some common traditional cleaning methods include:

| Method | Pros | Cons |

|---|---|---|

| Scrubbing | Effective for removing surface dirt | Time-consuming and labor-intensive |

| Sandblasting | Can remove tough stains and rust | Produces dust and can damage surfaces |

| Chemical Cleaning | Can dissolve stubborn contaminants | May require hazardous chemicals |

Laser Cleaning

Laser cleaning is a non-contact, environmentally friendly cleaning method that uses high-energy laser beams to remove contaminants from surfaces. This method is highly effective and can be used on a variety of materials without causing damage. Some advantages of laser cleaning include:

| Advantages | Traditional Cleaning Methods |

|---|---|

| Efficiency | Laser cleaning is faster and more efficient than traditional methods |

| Precision | Laser cleaning can target specific areas without affecting surrounding surfaces |

| Environmentally friendly | Laser cleaning does not produce waste or require harmful chemicals |

Conclusion

Overall, laser cleaning offers many advantages over traditional cleaning methods. It is faster, more precise, and environmentally friendly. While traditional cleaning methods may still be suitable for certain applications, laser cleaning is becoming increasingly popular for its efficiency and effectiveness.

#cleaning #traditionalcleaning #lasercleaning #efficiency #precision #environmentallyfriendly

long-tail phrases:

– comparison of traditional cleaning methods vs. laser cleaning

– advantages of laser cleaning over traditional methods

– efficiency and precision of laser cleaning

– environmentally friendly cleaning methods

Safety considerations when using lasers for decontamination

1. Eye protection: Lasers emit intense beams of light that can cause serious damage to the eyes. It is crucial to wear appropriate eye protection, such as laser safety goggles, when working with lasers for decontamination.

2. Training: Proper training is essential for anyone using lasers for decontamination. Operators should be familiar with the equipment, safety protocols, and emergency procedures to ensure safe operation.

3. Controlled environment: Laser decontamination should be conducted in a controlled environment to minimize the risk of accidents. This includes ensuring proper ventilation, adequate lighting, and clear workspaces.

4. Personal protective equipment: In addition to eye protection, operators should wear appropriate personal protective equipment, such as gloves and lab coats, to protect themselves from potential hazards.

5. Monitoring and supervision: It is important to have a designated safety officer or supervisor overseeing laser decontamination procedures to ensure compliance with safety guidelines and protocols.

6. Emergency response plan: In the event of an accident or injury, it is crucial to have an emergency response plan in place. This includes knowing how to shut off the laser, administering first aid, and contacting emergency services if necessary.

7. Regular maintenance and inspections: To ensure the safe and effective operation of laser decontamination equipment, regular maintenance and inspections should be conducted to identify and address any potential issues.

8. Compliance with regulations: It is important to comply with all relevant regulations and guidelines governing the use of lasers for decontamination to ensure the safety of operators and the environment.

In conclusion, while lasers offer a powerful and efficient method for decontamination, it is essential to prioritize safety considerations to prevent accidents and injuries. By following proper safety protocols, wearing appropriate protective equipment, and maintaining a controlled environment, operators can safely and effectively use lasers for decontamination.

#safety #lasers #decontamination #eye protection #training #personal protective equipment #emergency response plan #regulations

frazy kluczowe:

– Safety considerations for laser decontamination

– Laser decontamination safety precautions

– Importance of safety in laser decontamination procedures

Environmental benefits of laser cleaning in radioactive decontamination

Another environmental benefit of laser cleaning is the elimination of harmful chemicals. Many traditional decontamination methods rely on the use of corrosive or toxic chemicals to dissolve or remove contaminants. These chemicals can pose a risk to both the environment and human health if not properly handled and disposed of. Laser cleaning eliminates the need for these chemicals, making it a safer and more sustainable option for decontamination activities.

Furthermore, laser cleaning is a non-contact process, meaning that there is no physical contact between the cleaning equipment and the contaminated surface. This reduces the risk of spreading contaminants or damaging the underlying material, resulting in a more efficient and effective decontamination process. Additionally, laser cleaning can be performed remotely, allowing for decontamination activities to be carried out in hazardous or hard-to-reach areas without putting workers at risk.

| Environmental Benefits of Laser Cleaning | Traditional Decontamination Methods |

|---|---|

| Reduction of hazardous waste | Generation of large quantities of contaminated waste |

| Elimination of harmful chemicals | Reliance on corrosive or toxic chemicals |

| Non-contact process | Physical contact with contaminated surface |

In conclusion, laser cleaning offers significant environmental benefits in the decontamination of radioactive materials. By reducing hazardous waste, eliminating harmful chemicals, and providing a non-contact cleaning process, laser cleaning is a more sustainable and environmentally friendly option for decontamination activities. As we continue to seek ways to protect the environment and promote sustainability, laser cleaning stands out as a promising technology for addressing the challenges of radioactive decontamination.

#EnvironmentalBenefits #LaserCleaning #RadioactiveDecontamination #HazardousWaste #HarmfulChemicals #NonContactProcess #Sustainability

słowa kluczowe: laser cleaning, radioactive decontamination, environmental benefits, hazardous waste, harmful chemicals, non-contact process, sustainability

frazy kluczowe: environmental benefits of laser cleaning in radioactive decontamination, reduction of hazardous waste in decontamination, elimination of harmful chemicals in decontamination, non-contact cleaning process for radioactive materials.

Challenges and limitations of laser cleaning technology

Challenges:

1. Material compatibility: Laser cleaning may not be suitable for all types of materials, especially those that are sensitive to heat or have low thermal conductivity.

2. Surface damage: High-intensity lasers can potentially damage the surface being cleaned, especially if the laser parameters are not properly controlled.

3. Contaminant removal: Some contaminants may be difficult to remove using laser cleaning technology, especially if they are embedded deep within the material.

4. Cost: The initial investment in laser cleaning equipment can be high, making it less accessible for smaller businesses or individuals.

5. Regulatory compliance: There may be regulations and safety concerns associated with the use of lasers for cleaning purposes, which can pose challenges for implementation.

Limitations:

1. Complexity: Laser cleaning technology can be complex and require specialized knowledge and training to operate effectively.

2. Speed: The cleaning process with lasers can be slower compared to traditional methods, especially for larger surface areas.

3. Size limitations: The size of the laser cleaning equipment may limit its use on larger or irregularly shaped surfaces.

4. Environmental impact: While laser cleaning is considered environmentally friendly, there may still be concerns about the energy consumption and waste generated during the process.

In conclusion, while laser cleaning technology offers many benefits, there are still challenges and limitations that need to be addressed in order to fully realize its potential. By overcoming these obstacles, laser cleaning technology can become a more widely adopted and effective method for surface cleaning.

#laser #cleaning #technology #challenges #limitations

#materialcompatibility #surfacedamage #contaminantremoval #cost #regulatorycompliance #complexity #speed #sizelimitations #environmentalimpact

Case studies of failed laser cleaning attempts

Case Study 1:

Surface: Historic painting

Contaminant: Layers of dirt and grime

Outcome: Instead of removing the dirt, the laser caused discoloration and damage to the painting.

Cause: The laser intensity was set too high, leading to excessive heat and damage to the delicate paint layers.

Case Study 2:

Surface: Metal sculpture

Contaminant: Rust and corrosion

Outcome: The laser cleaning process removed the rust but also etched the surface, leaving behind visible marks.

Cause: The laser beam was not properly focused, resulting in uneven cleaning and surface damage.

Case Study 3:

Surface: Stone monument

Contaminant: Moss and algae

Outcome: The laser cleaning attempt did not effectively remove the moss and algae, leaving behind patches of green residue.

Cause: The laser wavelength was not suitable for targeting organic contaminants, leading to incomplete cleaning.

These case studies highlight the importance of proper training and expertise when using laser cleaning technology. It is essential to understand the characteristics of the surface and contaminants to ensure successful cleaning outcomes.

Hashtags: #laser #cleaning #failures

Keywords: laser cleaning, failed attempts, surface damage

Long-tail phrases: reasons behind failed laser cleaning attempts, importance of expertise in laser cleaning

Integration of laser cleaning technology into existing decontamination processes

One of the key benefits of laser cleaning technology is its ability to remove contaminants without the need for harsh chemicals or abrasive materials. This makes it an environmentally friendly option for decontamination, as it reduces the amount of hazardous waste generated during the cleaning process. Additionally, laser cleaning is a non-contact method, which means that it can be used to clean delicate surfaces without causing damage.

Another advantage of laser cleaning technology is its speed and efficiency. Traditional decontamination methods can be time-consuming and labor-intensive, requiring multiple steps and extensive manual labor. In contrast, laser cleaning can remove contaminants quickly and effectively, reducing downtime and increasing productivity.

Furthermore, laser cleaning technology is versatile and can be used to clean a wide range of surfaces, including metals, plastics, ceramics, and composites. This makes it a valuable tool for industries such as aerospace, automotive, electronics, and medical devices, where cleanliness and surface quality are critical.

To integrate laser cleaning technology into existing decontamination processes, companies must first assess their current cleaning methods and identify areas where laser cleaning could be beneficial. They should then invest in the necessary equipment and training to implement the technology effectively. Additionally, companies should consider the potential cost savings and environmental benefits of switching to laser cleaning technology.

In conclusion, the offers numerous benefits, including faster cleaning times, reduced waste generation, and improved surface quality. By adopting this technology, industries can enhance their cleaning processes and achieve higher levels of cleanliness and productivity.

#laser #cleaning #technology #decontamination #integration

frazy kluczowe:

– benefits of laser cleaning technology

– environmentally friendly decontamination

– non-contact cleaning method

– versatile surface cleaning

– cost savings and productivity improvements

Potential applications of laser cleaning in other industries

Electronics industry

- Laser cleaning can be used to remove contaminants from electronic components, ensuring optimal performance and longevity.

- It can also be used for precision cleaning of circuit boards and other delicate electronic parts.

Medical industry

- Laser cleaning can be utilized for sterilizing medical equipment and devices, reducing the risk of infections.

- It can also be used for cleaning surgical instruments and implants, ensuring a high level of hygiene.

Food industry

- Laser cleaning can be employed for cleaning food processing equipment, maintaining food safety standards.

- It can also be used for removing contaminants from packaging materials, ensuring the quality of food products.

Construction industry

- Laser cleaning can be used for removing graffiti from buildings and monuments, restoring their original appearance.

- It can also be used for cleaning construction materials such as concrete and metal, improving their durability.

Overall, laser cleaning technology has the potential to revolutionize various industries by providing a more efficient and environmentally friendly cleaning solution. With its precision and versatility, laser cleaning can address a wide range of cleaning challenges in different sectors.

#laser #cleaning #technology #industries #electronics #medical #food #construction

frazy kluczowe:

– laser cleaning technology in electronics industry

– potential applications of laser cleaning in medical industry

– laser cleaning in food processing equipment

– laser cleaning for graffiti removal in construction industry

Jeśli interesują Cię tanie sponsorowane publikacje SEO bez pośredników - skontaktuj się z nami:

Tel. 505 008 289

Email: ceo@codeengineers.com