- Types of contaminants removed by laser cleaning

- Process of laser cleaning for paper surfaces

- Applications of laser cleaning in paper manufacturing

- Case studies of failed laser cleaning projects in paper industry

- Advantages of laser cleaning for delicate paper surfaces

- Comparison of laser cleaning with chemical cleaning methods for paper surfaces

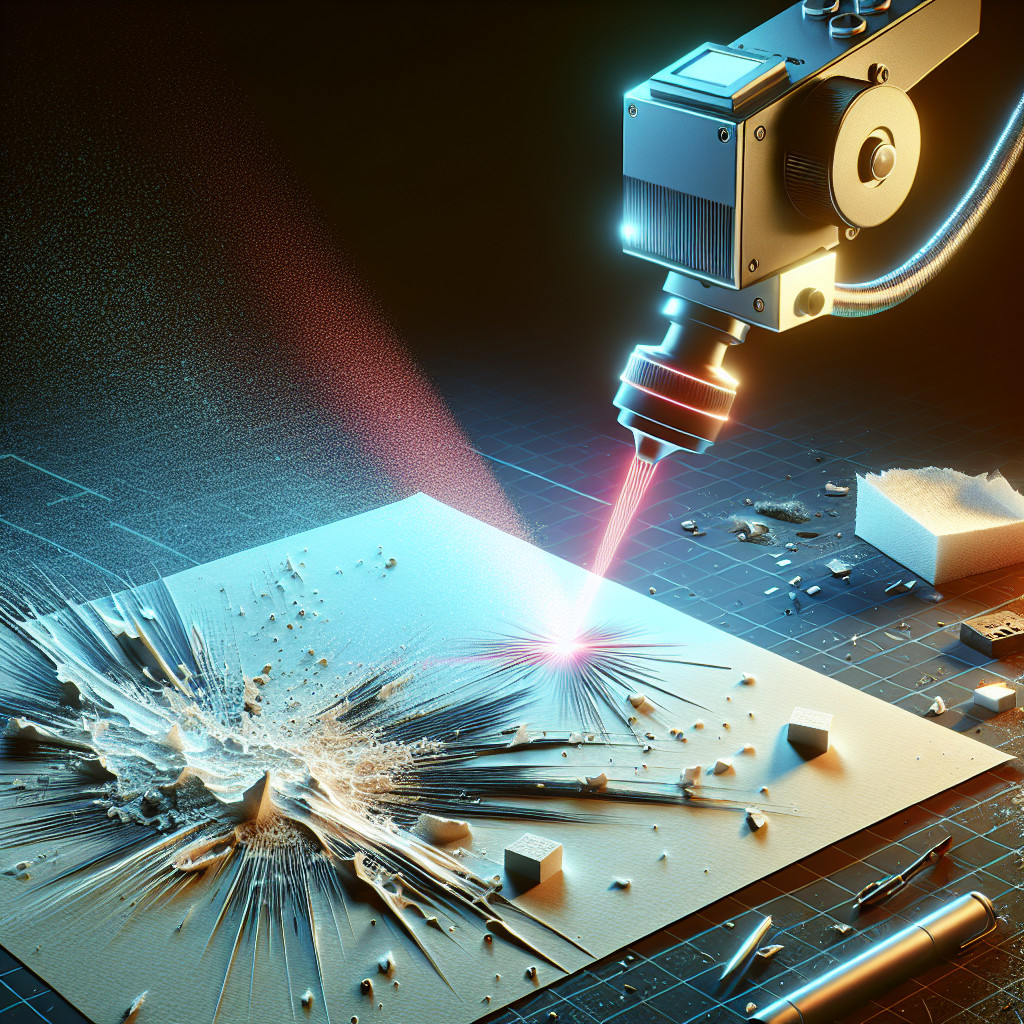

- Introduction to laser cleaning technology

- Case studies of successful laser cleaning projects in paper industry

Types of contaminants removed by laser cleaning

- Rust: Laser cleaning is particularly effective at removing rust from metal surfaces. The laser can quickly and efficiently vaporize the rust, leaving behind a clean and corrosion-free surface.

- Paint: Paint can be easily removed using laser cleaning. The intense heat generated by the laser can break down the paint, allowing it to be easily wiped away.

- Oil and grease: Laser cleaning can also be used to remove oil and grease from surfaces. The high temperatures produced by the laser can break down these contaminants, leaving behind a clean surface.

- Scale: Scale buildup on surfaces can be effectively removed using laser cleaning. The laser can vaporize the scale, leaving behind a smooth and clean surface.

- Corrosion: Laser cleaning is also effective at removing corrosion from metal surfaces. The laser can vaporize the corroded material, leaving behind a clean and smooth surface.

Overall, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from surfaces. Whether you need to remove rust, paint, oil, grease, scale, or corrosion, laser cleaning can provide a fast and effective solution.

Hashtags: #laser #cleaning #contaminants #rust #paint #oil #grease #scale #corrosion

Keywords: laser cleaning, contaminants, rust, paint, oil, grease, scale, corrosion

Long-tail phrases: laser cleaning for rust removal, efficient removal of paint using laser, benefits of laser cleaning for oil and grease removal

Process of laser cleaning for paper surfaces

Benefits of laser cleaning for paper surfaces:

– Non-contact cleaning method: Laser cleaning does not require any physical contact with the paper surface, reducing the risk of damage or abrasion.

– Precision cleaning: The focused laser beam can target specific areas on the paper surface, ensuring thorough and precise cleaning.

– Environmentally friendly: Laser cleaning does not involve the use of chemicals or solvents, making it a sustainable and eco-friendly cleaning method.

– Time-saving: Laser cleaning is a fast and efficient process that can be completed in a fraction of the time compared to traditional cleaning methods.

The involves the following steps:

1. Preparation: The paper surface is inspected to determine the type and extent of contamination that needs to be removed.

2. Calibration: The laser parameters, such as power, wavelength, and pulse duration, are adjusted to suit the specific requirements of the cleaning process.

3. Cleaning: The laser beam is directed onto the contaminated areas of the paper surface, causing the contaminants to evaporate or sublimate without damaging the paper itself.

4. Inspection: After cleaning, the paper surface is inspected to ensure that all contaminants have been successfully removed.

5. Finishing: If necessary, the paper surface can be further treated or coated to protect it from future contamination.

Overall, laser cleaning for paper surfaces is a highly effective and efficient method that offers numerous benefits over traditional cleaning methods. By utilizing this cutting-edge technology, industries can improve the quality and longevity of their paper products while also reducing their environmental impact.

#laser #cleaning #paper #surfaces

Keywords: laser cleaning, paper surfaces, technology, efficiency, precision, environmentally friendly

Long-tail phrases: laser cleaning for paper packaging, laser cleaning for conservation purposes, laser cleaning for printing industry.

Applications of laser cleaning in paper manufacturing

- Roll cleaning: Laser cleaning is used to remove contaminants and buildup from paper machine rolls, ensuring smooth and efficient operation.

- Nozzle cleaning: Laser cleaning can effectively remove blockages and buildup from nozzles, improving the quality of the paper produced.

- Dryer cleaning: Laser cleaning is used to remove debris and contaminants from dryer surfaces, preventing defects in the paper.

- General equipment cleaning: Laser cleaning can be used to clean various types of equipment in the paper manufacturing process, such as screens, pumps, and valves.

Overall, laser cleaning offers a cost-effective and environmentally friendly solution for maintaining cleanliness in paper manufacturing facilities. By reducing the use of chemicals and abrasive materials, laser cleaning helps to minimize waste and improve the overall sustainability of the industry.

Keywords: laser cleaning, paper manufacturing, machinery, equipment, environmentally friendly

Long-tail phrases: laser cleaning technology in paper manufacturing, non-contact cleaning solution, environmentally friendly cleaning method

#laser #cleaning #paper #manufacturing #machinery #environmentallyfriendly #technology #equipment #noncontactcleaning #sustainability #longtailphrases #abrasivematerials #chemicals

Case studies of failed laser cleaning projects in paper industry

Case Study 1:

| Issue | Cause | Solution |

|---|---|---|

| Uneven cleaning | Improper calibration of laser settings | Re-calibrate laser settings and test on a small area before full-scale cleaning |

Case Study 2:

| Issue | Cause | Solution |

|---|---|---|

| Damage to paper surface | Excessive laser power | Adjust laser power settings and conduct test runs to determine optimal power level |

These case studies highlight the importance of proper calibration and testing before implementing laser cleaning projects in the paper industry. By identifying potential issues and addressing them proactively, companies can avoid costly failures and achieve successful results with laser cleaning technology.

Keywords:

laser cleaning, paper industry, failed projects, calibration, testing

Long-tail phrases:

reasons behind failed laser cleaning projects, importance of proper calibration, successful implementation of laser cleaning technology

#laser #cleaning #paperindustry #failedprojects #calibration #testing

laser cleaning, paper industry, failed projects, calibration, testing

reasons behind failed laser cleaning projects, importance of proper calibration, successful implementation of laser cleaning technology

Advantages of laser cleaning for delicate paper surfaces

- Gentle cleaning: Laser cleaning is a non-contact method that uses a focused beam of light to remove contaminants from the surface of paper. This gentle approach ensures that the paper remains intact and undamaged during the cleaning process.

- Precision: Laser cleaning allows for precise control over the cleaning process, making it ideal for removing dirt and stains from delicate paper surfaces without affecting the underlying material.

- No chemicals: Unlike traditional cleaning methods that rely on harsh chemical solvents, laser cleaning is a chemical-free process that is safe for both the environment and the paper being cleaned.

- Efficiency: Laser cleaning is a fast and efficient way to clean delicate paper surfaces, saving time and labor compared to traditional cleaning methods.

- Versatility: Laser cleaning can be used on a wide range of paper materials, including historical documents, artwork, and manuscripts, making it a versatile cleaning solution for museums, archives, and libraries.

In conclusion, laser cleaning offers a range of advantages for delicate paper surfaces, including gentle cleaning, precision, no chemicals, efficiency, and versatility. This innovative technology provides a safe and effective way to clean fragile paper materials without causing any damage.

#laser cleaning, delicate paper surfaces, advantages, gentle cleaning, precision, no chemicals, efficiency, versatility, fragile paper materials, innovative technology.

Comparison of laser cleaning with chemical cleaning methods for paper surfaces

Laser cleaning:

– Utilizes a high-energy laser beam to vaporize contaminants on the surface of the paper

– Does not require the use of chemicals, making it an environmentally friendly option

– Can be used on delicate paper surfaces without causing damage

– Provides precise control over the cleaning process, allowing for targeted removal of contaminants

Chemical cleaning methods:

– Involve the use of solvents or cleaning agents to dissolve and remove contaminants from the paper surface

– Can be effective in removing tough stains and dirt, but may also damage the paper if not used properly

– May leave behind residue or chemical odors on the paper surface

– Require proper ventilation and safety precautions due to the use of chemicals

Comparison:

– Laser cleaning is more environmentally friendly than chemical cleaning methods, as it does not involve the use of harmful chemicals

– Laser cleaning provides more precise control over the cleaning process, allowing for targeted removal of contaminants without damaging the paper surface

– Chemical cleaning methods may be more effective in removing tough stains and dirt, but they also carry the risk of damaging the paper if not used properly

In conclusion, the choice between laser cleaning and chemical cleaning methods for paper surfaces depends on the specific cleaning needs and requirements. While laser cleaning offers a more environmentally friendly and precise cleaning option, chemical cleaning methods may be more effective in certain situations. It is important to consider the potential risks and benefits of each method before making a decision.

#laser cleaning, #chemical cleaning, #paper surfaces, #environmentally friendly, #precise control, #removing contaminants, #cleaning methods

frazy kluczowe:

– laser cleaning vs chemical cleaning for paper surfaces

– comparison of laser cleaning and chemical cleaning methods

– effectiveness of laser cleaning on paper surfaces

– environmentally friendly cleaning options for paper

– precise control in removing contaminants from paper surfaces

Introduction to laser cleaning technology

How Laser Cleaning Works

Laser cleaning works by directing a laser beam onto the surface of an object, where it vaporizes or ablates the contaminants or coatings. The intense heat generated by the laser beam causes the unwanted material to break down and be removed from the surface. This process is non-contact, meaning that there is no physical contact between the laser and the surface being cleaned, reducing the risk of damage to delicate materials.

Applications of Laser Cleaning

Laser cleaning technology has a wide range of applications across various industries. Some common uses include:

| Industry | Application |

|---|---|

| Automotive | Removing paint and rust from car bodies |

| Aerospace | Cleaning turbine blades and engine components |

| Electronics | Removing solder and flux residues from circuit boards |

Benefits of Laser Cleaning

There are several benefits to using laser cleaning technology, including:

- Environmentally friendly – no chemicals or solvents are required

- High precision – can target specific areas without affecting surrounding surfaces

- Efficient – reduces cleaning time and labor costs

- Non-abrasive – gentle on delicate materials

Conclusion

Laser cleaning technology is a versatile and efficient method of removing contaminants from surfaces in a wide range of industries. Its non-contact nature and precision make it a popular choice for applications where traditional cleaning methods may be ineffective or damaging. As technology continues to advance, laser cleaning is likely to become even more widespread in the future.

#laser #cleaning #technology #industrial #applications #efficiency #precision #noncontact #environmentallyfriendly

słowa kluczowe: laser, cleaning, technology, industrial, applications, efficiency, precision, non-contact, environmentally friendly

frazy kluczowe: laser cleaning technology applications, benefits of laser cleaning, how laser cleaning works, laser cleaning in aerospace industry, laser cleaning in automotive industry, laser cleaning in electronics industry.

Case studies of successful laser cleaning projects in paper industry

Case Study 1: Cleaning of printing rollers

In a paper mill, the printing rollers used for printing patterns on paper were getting clogged with ink residues, leading to poor print quality. Traditional cleaning methods were time-consuming and ineffective. A laser cleaning system was installed to clean the printing rollers without the need for disassembly. The laser beam was able to remove the ink residues quickly and efficiently, resulting in improved print quality and reduced downtime.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

| Dirty and clogged printing rollers | Clean and smooth printing rollers |

Case Study 2: Removal of adhesive residues

In another paper mill, adhesive residues were causing issues with the bonding of paper layers in the production process. Traditional cleaning methods using solvents were not effective and posed environmental risks. A laser cleaning system was used to remove the adhesive residues without the need for chemicals. The laser beam was able to vaporize the residues, leaving the paper layers clean and ready for bonding.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

| Adhesive residues on paper layers | Clean paper layers ready for bonding |

Case Study 3: Cleaning of paper cutting equipment

In a paper processing plant, the cutting equipment was getting contaminated with paper dust and debris, leading to reduced cutting precision. Traditional cleaning methods using brushes and compressed air were not effective in removing the contaminants. A laser cleaning system was used to clean the cutting equipment without the need for disassembly. The laser beam was able to remove the paper dust and debris, restoring the cutting precision and improving productivity.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

| Contaminated cutting equipment | Clean cutting equipment with improved precision |

These case studies demonstrate the effectiveness of laser cleaning technology in the paper industry. By using laser cleaning systems, paper mills can improve efficiency, reduce downtime, and ensure high-quality production. Laser cleaning is a sustainable and environmentally friendly solution for removing contaminants from paper processing equipment.

#laser #cleaning #paper industry #case studies #efficiency #contaminants #printing rollers #adhesive residues #paper cutting equipment #environmentally friendly #sustainable solution

frazy kluczowe:

– laser cleaning technology in paper industry

– successful laser cleaning projects

– paper processing equipment

– improved print quality

– removal of adhesive residues

– cutting precision

– environmentally friendly solution

– high-quality production

Jeśli interesują Cię tanie sponsorowane publikacje SEO bez pośredników - skontaktuj się z nami:

Tel. 511 005 551

Email: biuro@codeengineers.com

- Software House Poland and cybersecurity best practices. - 29 September 2025

- Laser cleaning for removing contaminants from paper surfaces - 24 May 2024

- Cele i korzyści z ukończenia kursu trenera personalnego - 18 October 2023